These porcelain lidded boxes have been finished with volatile coloured glazes. The Burgundy red glaze of the left box, and the cobalt blue glaze of the box to the right are accentuated by a thin white strip around the box.

Length 15 cm

Width 11 cm

Height 10.4 cm

Length 11 cm

Width 8 cm

Height 7.8 cm

Gottfried Palatin

- Porcelain maker

- Mödling, Austria

- Master Artisan

- Recommended by Rainald Franz

By appointment only

+43 69912628297

The geometer of boxes

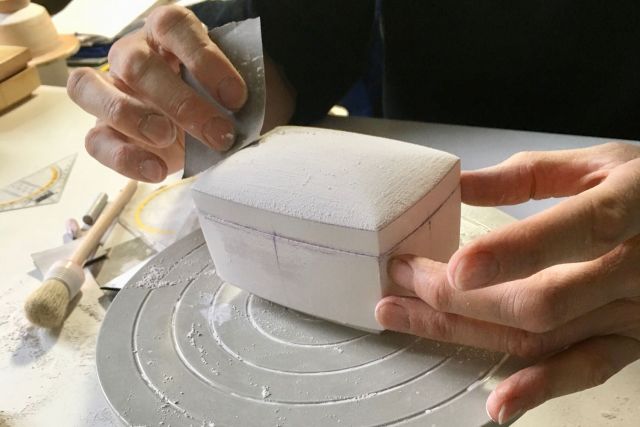

- • Gottfried creates geometrical forms

- • His porcelain boxes are distinctive

- • He creates the models from alabaster plaster

Gottfried Palatin’s first passion was drawing, the discovery and exploration of geometry and perspectives with a pen and a piece of paper. It wasn’t until art lessons in grammar school when he got a lump of clay in his hands and suddenly realized that he was much more interested in being able to shape objects in three dimensions with his own hands. This eureka moment led to studies at the Stoob School of Ceramics, followed by extensive study visits to Asia. In 1984, Gottfried joined the Viennese porcelain art studio of Prof. Gundi Dietz, where he could fully immerse himself in the world of porcelain and started to develop his own design language. After working for numerous renowned manufacturers, in 2014 he decided to solely focus on his unique collection of porcelain boxes.

Read the full interviewWorks

Photo: ©Gottfried Palatin

Photo: ©Gottfried Palatin

This elegant lidded box hand been handcrafted from porcelain and finished with a bold gold glaze.

Length 10.4 cm

Width 7.5 cm

Height 8.6 cm

Photo: ©Gottfried Palatin

This oval porcelain lidded box has been finished with volatile bright red coloured glaze. The colour of the glaze is further accentuated by a thin white line that makes its way around the opening of the box, distinguishing container and lid.

Length 13.7 cm

Width 8.7 cm

Height 9.9 cm

Photo: ©Gottfried Palatin

This rectangular porcelain lidded box has been finished with volatile green hue glaze. The colour of the glaze is further accentuated by thin white lines around the contours of the box.

Length 11.8 cm

Width 4.9 cm

Height 7.5 cm

Photo: ©Gottfried Palatin

This geometric porcelain lidded box has been finished with a turquoise blue seladon glaze. The colour of the glaze is further accentuated by thin white line around the contours of each hexagon.

Length 7.3 cm

Width 5 cm

Height 5.1 cm